What Concrete Slump Do You Need For Your Project?

When working with concrete it is essential that you first test the consistency – or concrete slump – of the mix before you lay it, in order to make sure that the concrete is workable and able to set properly.

The most popular way we do this is by performing a slump test.

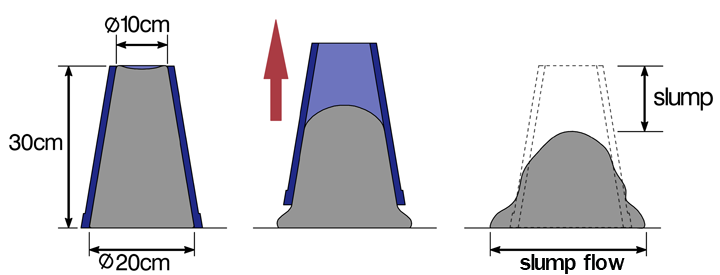

This is done by filling a metal cone also known as an Abrams cone) with concrete mix before carefully removing the cone and measuring how much of the concrete stays in place.

The concrete slump is determined by calculating the difference between the height of the mould and that of the highest point of specimen. If the concrete mix is too wet then it will “slump” down one side and will need to be remixed. This is because concrete is weaker and more susceptible to cracking when the mix is too wet.

If it is too dry then there will be no slump at all and you may need to add more water to the mix.

There are four categories of concrete slump, however in order for your concrete to be workable, you need to aim for a true slump.

A true slump is where the top of the concrete mass slumps evenly all the way around, however the bulk of the mass stays in one place. If any other result is achieved from the slump test you will have to remix the concrete. The other results are as follows:

Collapse Slump – A collapse slump is exactly how it sounds. If you perform the test and the concrete mass has collapsed completely then this is what’s known as a collapse slump and it means you’ve added to much water.

Shear Slump – In a shear slump only one side of the concrete mass will remain in place. If one side has dropped it is known as a shear slump.

Zero Slump – This is the result of the concrete mix being too dry and will result in no slump at all.

Different measures of Concrete Slump for different projects …

Different types of project normally require different degrees of concrete slump.

For example the concrete used in road making is often very dry and has a low degree of workability, therefore requiring the use of power operated machines. For projects such as this, the slump will normally measure between 0-1 inches.

Other projects such as driveways, paving and the use of slabs, will require a greater degree of workability and so the concrete slump will need to be slightly greater. Driveways for instance require a maximum slump of 5 inches.

All our brands of ready mixed concrete have already been slump tested.

You can choose exactly what consistency of concrete you need by visiting our online ordering page. We offer five different types of concrete slump, ranging from dryer mixes (30 – 50 slump) and wetter mixes (90-120 slump).

Wetter mixes are more commonly used for trench filled foundations where a high flow is required whereas dryer mixes; approx 50-70 slump, are used mainly in simple strip footings and for hard standing slabs.